Tungsten rod tungsten rod

The office address of Luoyang Shunluan Rare Metal Materials Co., Ltd. is located in the west section of Zheng Village, Anle Town, Luolong District, Luoyang City, a long-lasting city-Luoyang. It was registered and established in Guanlin Branch of Luoyang Administration for Industry and Commerce on May 23, 2017. The capital is 3 million yuan, in the 2 years of the company's development and growth. We always provide customers with good products and technical support, and sound after-sales service. Our company mainly deals in the sales and processing of rare metal materials and non-ferrous metal materials; the design and development of industrial furnaces; and the import and export of goods. We have good products and professional sales and technical team, our company belongs to the Luoyang metal materials agent to join the company industry.

Category:

Key words:

Tungsten rod tungsten rod

Hotline:

Product Description

Characteristics of molybdenum plate products

Our company can carry out vacuum annealing treatment and leveling treatment on molybdenum plate. The plates produced by our company are all cross-rolled, and the grain size of the injection is controlled during the rolling process. Therefore, the plate has good bending and stamping performance.

Molybdenum plate Molybdenum foil

Molybdenum plate is made by the rolling process of molybdenum slab after pressing and sintering. Usually 2-30mm thickness is called molybdenum plate, 0.2-2mm thickness is called molybdenum sheet, 0.2mm thickness is called molybdenum foil. Molybdenum plates of different thicknesses need to be manufactured by different types of rolling mills. Thinner molybdenum sheets and molybdenum foils have better crimping performance and can be manufactured by continuous rolling mills with tension and provided in rolls, which are called molybdenum strips.

There are 9 sets (sets) of rolling mills of different specifications, which can provide users with molybdenum plates, molybdenum sheets, molybdenum foils and molybdenum strips of various thicknesses and widths. In addition to pure molybdenum plates, molybdenum lanthanum alloy (high temperature molybdenum) plates and molybdenum zirconium titanium alloy (TZM) plates can also be manufactured.

|

厚度 Thickness mm |

Limit width mm |

Limit Length mm |

|

0.05 ~ 0.10 |

150 |

L |

|

0.10 ~ 0.15 |

300 |

1000 |

|

0.15 ~ 0.20 |

400 |

1500 |

|

0.20 ~ 0.30 |

650 |

2540 |

|

0.30 ~ 0.50 |

750 |

3000 |

|

0.50 ~ 1.0 |

750 |

5000 |

|

1.0 ~ 2.0 |

600 |

5000 |

|

2.0 ~ 3.0 |

600 |

3000 |

|

> 3.0 |

600 |

L |

Molybdenum plate specifications

|

厚度 Thickness mm |

Limit Width mm |

Limit Length mm |

|

1.0 |

50 |

100 |

|

2.0 |

80 |

150 |

|

3.0 |

100 |

300 |

|

4.0-5.0 |

200 |

600 |

|

5.0-10.0 |

300 |

1200 |

|

> 10.0 |

300 |

1600 |

Tungsten and molybdenum rolled products are widely used in the late stage of deep processing.

Sapphire crystal furnace and vacuum furnace tungsten and molybdenum heat shield, tungsten and molybdenum heating body, furnace support frame, carrying boat, etc;

Diversion cylinder, molybdenum hook, lifting ring, feeder, etc. in monocrystalline silicon industry;

Vacuum coating industry to produce tungsten boat, molybdenum boat, cathode, tungsten target, molybdenum target;

High temperature resistant parts, such as components of ion sources in ion implantation equipment;

Medical equipment industry to produce CT collimator blades;

Semiconductor and electronics industry heating body, LED chip substrate, MOCVD machine with molybdenum gas ring.

Tungsten Products

Product chemical and physical properties

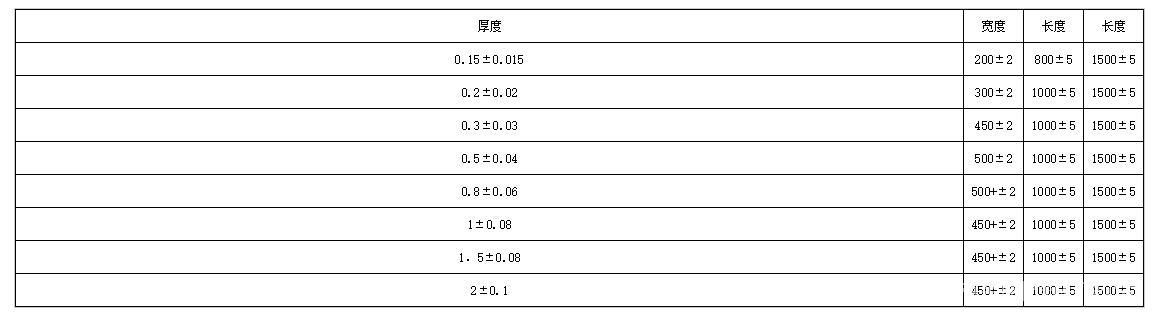

(1) Tungsten plate: purity above 99.95

(2) density: up to 19.2g/cm3

(3) Flatness: ≤ 5%

(4) Elongation ≥ 3%

Supply standard: GB/T 3875-2006

Tungsten sheet is mainly used in the manufacture of heating elements, heat shields and parts of electric vacuum electric light sources of electric vacuum furnaces. Tungsten boats made of tungsten sheet by stamping are used for vacuum coating vessels, medical diagnosis and treatment equipment, radiation and interference shielding.

Previous Page

Next Page

Previous Page

Next Page

Related Products

Online message

If you have any suggestions or feedback to our company, please fill in the relevant information on this page and submit it. A staff member will contact you in time, or please call us directly.